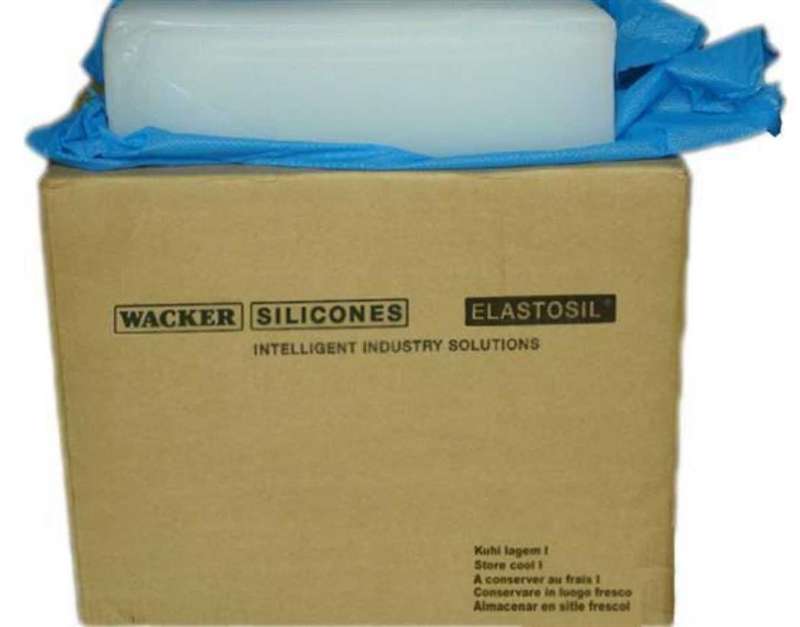

6 X Elastosil R401/70

17 were available / new

R10.00

minimum increment

Shipping

R35.00 Standard shipping using one of our trusted couriers applies to most areas in South Africa. Some areas may attract a R30.00 surcharge. This will be calculated at checkout if applicable.

Check my rate

Check my rate

The seller has indicated that they will usually have this item

ready to ship within 3 business days.

Shipping time depends on your delivery address.

The most accurate delivery time will be calculated at checkout,

but in general, the following shipping times apply:

Standard Delivery

| Main centres: | 1-3 business days |

| Regional areas: | 3-4 business days |

| Remote areas: | 3-5 business days |

Seller