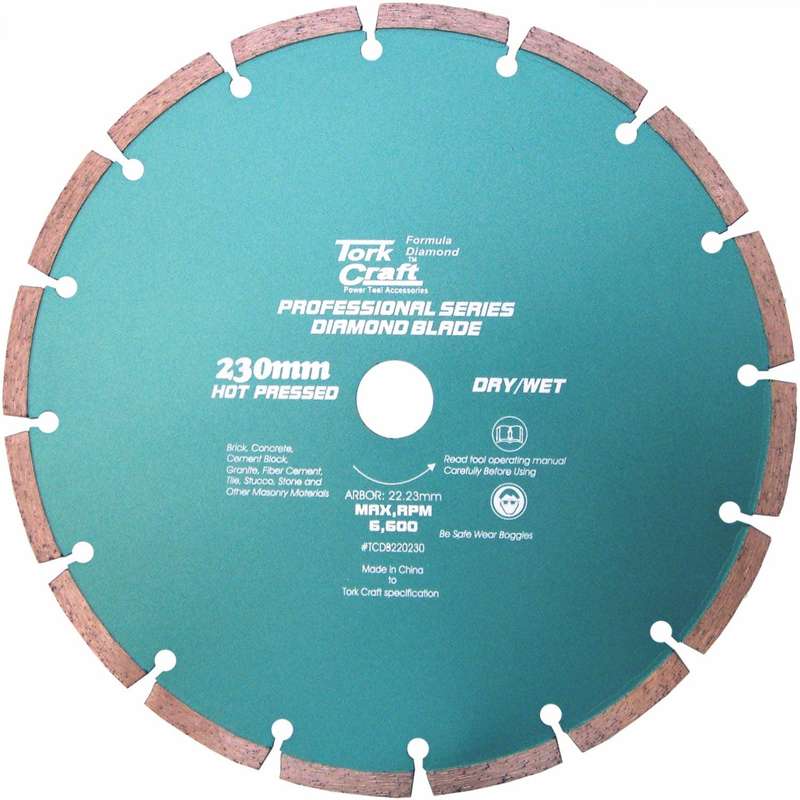

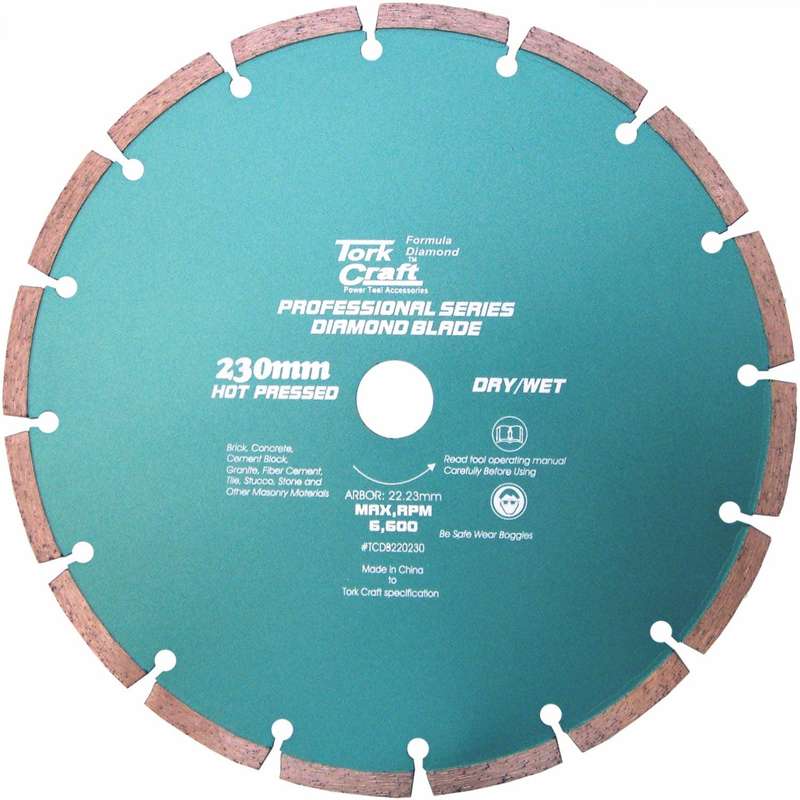

Diamond Blade 230 Mm Segmented Hot Pressed

Check my rate

| Main centres: | 1-3 business days |

| Regional areas: | 3-4 business days |

| Remote areas: | 3-5 business days |

| Main centres: | 1-3 business days |

| Regional areas: | 3-4 business days |

| Remote areas: | 3-5 business days |

Type:

Hot Press And Segmented.

A Diamond Blade Is Composed Of A Circular Steel Core And The Diamond

Impregnated Segments. The Segments Are Seperated By Slots In The Core.

These

Slots Assist In Cooling The Blade During Operation By Allowing Water (Wet

Cutting) Or Air (Dry Cutting) To Flow Between The Segments. The Segments Or Rims

Are A Mixture Of Diamond Powder And Metal Powders. The Diamonds Are Industrial

Diamonds Of Different Sizes And Qualities Depending On The Material To Be Cut As

Well A The Blade Type.

The Individual Diamond Crystals Exposed On The Leading Edge And The Sides Of

The Segment Or Rim Carry Out The Cutting. The Operator Pushes The Rotating Blade

Into The Material And The Surface Diamonds Thus Exposed Mill A Groove In The

Material. When The Blade Mills The Material, The Latter Exerts Wear On The

Blade. During Cutting The Exposed Diamonds May Crack

Or Break. The Material Simultaneously Starts To Abrade The Metal Matrix, Which

Releases More Diamonds.

The More Abrasive The Material, The More Rapid

The Tendency To Wear Down The Matrix. Blades For Cutting Hard, Denseless

Abrasive Materials (Such As Tile, Bricks, Stone Or Cured Concrete), Require

A Softer Metal Matrix.

This Will Wear Down Faster, Replacing The Worn Diamonds

Fairly Quickly So That The Blade Continues To Cut.

Blades For Cutting Soft,

Abrasive Materials (Such As Green Concrete And Asphalt), Must Have&Nbsp; A Hard,

Abrasion Resistant Metal Matrix In Order To Retain The Diamonds For A Longer

Time.

Water Will Prevent The Blade From Overheating:

It Will Greatly Reduce The Amount Of Harmful Dust Created By Cutting. Remove The

Slurry From The Cut, And Extend The Life Of The Blade.