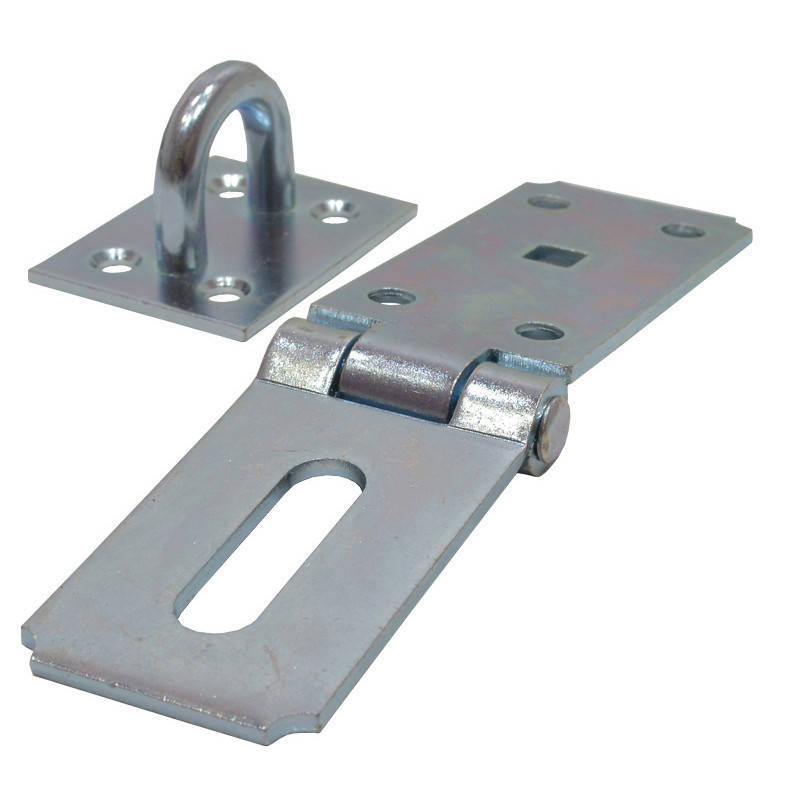

Heavy-duty zinc-plated 4 mm thick steel plate hasp and staple (hinged pin type)

Check my rate

| Main centres: | 1-3 business days |

| Regional areas: | 3-4 business days |

| Remote areas: | 3-5 business days |

| Main centres: | 1-3 business days |

| Regional areas: | 3-4 business days |

| Remote areas: | 3-5 business days |

A hasp and staple is designed for securing toolboxes, doors, gates, garages, warehouses, workshops, and sheds in heavy-wearing places requiring a high level of security and is ideal for lock-up-and-go applications and is a key defence against undesirable intruders gaining access to all manner of essential equipment. Rural properties, farms and industrial premises are the biggest users of these hasps and staples.

There are 8 by 7 mm diameter pre-drilled countersunk holes for easy fixing with 2 by 9 mm square holes. Fixing the hasp and staple will require 8 by 6 mm diameter screws and 2 by 6 mm diameter carriage bolts for added security, depending on your application. It can be used together with a heavy-duty padlock and is suitable for all weather conditions. (Note: Padlock and screw fixings are not included.).

The hasp's back fixing plate with fixing holes is manufactured from 4 mm thick zinc-plated steel and is 110 mm long to the centre of the hinge pin and is 45 mm wide by 4 mm thick. The hasp's slotted locking plate has a slot of 50 mm long by 12.5 mm wide, and the plate is 95 mm long by 4 mm thick. Both sets of plate fixing holes may be drilled/reamed out to suit thicker diameter fixings.

The staple is 45 mm by 64 mm by 4 mm thick with a 10 mm diameter steel shackle with an internal diameter of 20 mm at the centre of the shackle, which is suitable for a padlock shackle diameter of up to 16 mm.