Buying these from Switzerland will set you back 100 Swiss Frank R770 in courier costs alone !!!!

More here : http://www.intersema.ch (follow link to buying samples)

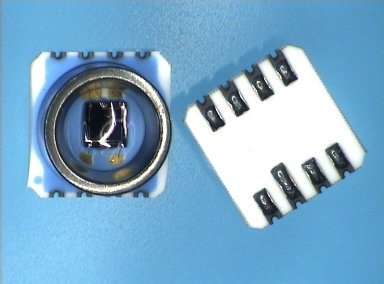

Pressure Sensor by Intersema Sensoric SA SWITZERLAND

Model : MS5407-AM 7 bar 392 mV Full Scale output voltage

The MS5407-AM is qualified referring to ISO Standard 2281 and can withstand an absolute pressure of

21 bar in salt water or 200 m water respectively

· Piezoresistive silicon micromachined sensor

· Miniature surface mount 6.2 x 6.4 mm

· Low noise, high sensitivity, high linearity

PIN DESCRIPTION

OUT- 1 Negative output voltage of Wheatstone bridge

GND 2 Ground

VS+ 3 Supply voltage of Wheatstone bridge

OUT+ 4 Positive output voltage of Wheatstone bridge

GENERAL

The MS5407 is a miniaturised absolute pressure sensor series which has been designed for surface mounting

applications. Its main advantages are the high reliability of the semiconductor sensor and a design which makes

it suitable for applications requiring small-scale and cost-efficient solutions.

The sensor element of the MS5407 consists of a micromachined silicone membrane with Pyrex glass waferbonded under vacuum to the backside for reference pressure. Implanted resistors make use of the piezoresistive effect to sense pressure applied to the membrane. The sensor is mounted in a special process allowing best-offset stability making the part suitable for direct PCB assembly.

HUMIDITY, WATER PROTECTION

The MS5407 carries a anticorrosive and antimagnetic stainless steel protection cap filled with silicone gel for

enhanced protection against humidity. The properties of this gel ensure function of the sensor even when in

direct water contact. This feature can be useful for waterproof watches or other applications, where direct water

contact cannot be avoided. Nevertheless the user should avoid drying of hard materials like for example salt

particles on the silicone gel surface. In this case it is better to rinse with clean water afterwards. Special care

has to be taken to not mechanically damage the gel. Damaged gel could lead to air entrapment and

consequently to unstable sensor signal, especially if the damage is close to the sensor surface.

The metal cap is fabricated of special anticorrosive stainless steel in order to avoid any corrosive battery effects

inside the final product.

For underwater operations as specified in ISO Standard 2281 it is important to seal the sensor with a rubber O ring around the metal cap. Any salt water coming to the contact side (ceramic and pads) of the sensor could

lead to permanent damage. Especially for "water-resistant 100 m" watches it is recommended to provide a

stable mechanical pusher from the backside of the sensor. Otherwise the overpressure might push the sensor

backwards and even bend the electronic board on which the sensor is mounted.

LIGHT SENSITIVITY

The MS5407 is sensitive to sunlight, especially to infrared light sources. This is due to the strong photo effect of

silicon. As the effect is reversible there will be no damage, but the user has to take care that in the final product

the sensor cannot be exposed to direct light during operation. This can be achieved for instance by placing

mechanical parts with holes in such that light cannot pass.