| Main centres: | 1-3 business days |

| Regional areas: | 3-4 business days |

| Remote areas: | 3-5 business days |

No matter which grinding machine you use the most difficult part in sharpening woodturning tools is to exactly replicate the shape and the edge angle. Now we offer the Bench Grinder Mounting Set BGM-100 which makes the patented Tormek woodturning system also available for bench grinders.

Why would Tormek, the pioneer in water cooled sharpening, introduce their jigs also for bench grinders?

We believe that the water cooled Tormek machine is superior in sharpening virtually every edge tool in your shop. However, there is no secret that when it comes to woodturning tools the initial shaping can be done faster on a bench grinder. We know that some woodturners dedicated to Tormek also have access to a bench grinder and use it for the first rough shaping. It is difficult to control by hand and it is easy to remove more steel than necessary. Now you can use the same precise Tormek jigs through the whole sharpening process. There is no longer trial and error in getting the right shape on the bench grinder. You can benefit from the fast steel removal on the bench grinder and also get the finest surface on the Tormek water cooled grindstone and the leather honing wheel all in one jig system.

If you do not yet have a Tormek machine you can still benefit from the precise Tormek jig system on your bench grinder and easily get the desired shape and edge angle. Since the Tormek system controls these factors, the tools will behave in exactly the same predictable way all the time at the lathe. The principle for setting the shape and edge angle is the same regardless of which machine you use. If you later choose to add a Tormek to your shop, you will already have the jigs you need for your turning tools.

The Key to Precise Replication

The Turning Tool Setter TTS-100 takes the guesswork out of sharpening and is the key to the Tormek sharpening system for woodturning tools. There is no longer any need for trial and error to get the best edge shape for each turning operation. You just set the jig and get the shape you have selected. Thanks to the patented design it works on any stone diameter. So you can go from a 6 wheel to a 10 grindstone and achieve the same shape. The TTS-100 works on all Tormek models and together with the BGM-100 Mounting Set it can also be used on a standard bench grinder.

How does it work?

Three factors determine the shape of a gouge or a skew; the Jig Setting JS, the protrustion P and the distance to the stone of the Universal Support. By repeating them at each shaping or sharpening you will get an exact replication of the shape and edge angle every time.

JIG SETTING = JS

PROTRUSION = P

DISTANCE TO STONE

Shaping and Sharpening

The Tormek method makes a distinction between the shaping and sharpening (or re-sharpening) of a tool. When shaping you remove steel to achieve the shape and edge angle you want. When sharpening you just touch up an existing shape to renew the sharpness. Once you have created the desired shape on the tool, it is an easy task to re-sharpen the tool exactly to the same shape every time.

If you have a Tormek machine, you can create the initial shape on your bench grinder and finish the sharpening on your Tormek water cooled grindstone. You get the best of two worlds; the fast steel removal from your high speed bench grinder and the fine surface from your fine water cooled grindstone and the leather honing wheel. A finer edge gives the wood a smoother finish with less need for sanding. A finer edge also stays sharp longer than a rough edge.

Which Shape Should I Use?

The Turning Tool Setter is delivered with a Selection Chart where you can see which shape is suitable for your current type of turning. These geometries are recommended by experienced woodturners and recognized woodturning training workshops around the world, e.g. Craft Supplies in the USA and Drechselstube Neckarsteinach in Germany. Of course you can also sharpen with geometries other than the shapes provided by the TTS-100 Setter.

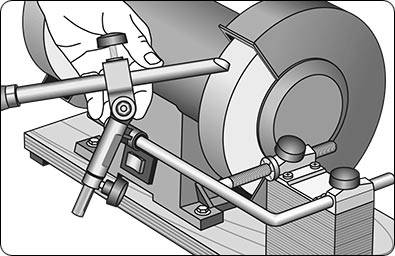

Bench Grinder Mounting Set BGM-100

The package includes a Universal Support, a horizontal base, hardware, feet for the base you will build, and very comprehensive instructions on how to properly build your base and how to safely use the dry grinder to shape your tools.

Mount the set on either side of the grinder, or buy two sets and mount on both sides and you get a versatile sharpening system.

PDF BGM-100 Mounting Instruction

Which jigs can I use on a bench grinder?

With the BGM-100 you can use all Tormek woodturning jigs on your bench grinder; the Gouge Jig SVD-185, the Multi Jig SVS-50 and the Tool Rest SVD-110.

About Bench Grinders

Using the right type of grinding wheel

Not all grinding wheels are suitable for the precision sharpening of edge tools. The standard wheels mounted on the grinder are often too hard and become glazed easily and clogged, which reduces steel removal and causes overheating of the tool. Worn grains must wear away so that new ones come into play. If not the grains will rub instead of cutting, which will increase the friction and heat development. Use an aluminium oxide wheel with the right binding not too hard to avoid glazing and not too soft to avoid grooves.

Wheel Surface

The wheel surface must be kept fresh and clean. Use a diamond wheel dresser to maintain the surface in a good shape and condition.

Influence of heat on HSS steel

HSS steel can stand a much higher temperature than carbon steel without decreasing the hardness. However, at the very tip of the edge, which is very thin, the temperature can easily rise to a level which will affect the hardness. Therefore grind cautiously at the tip of the edge and do not allow it to become blue. Overheating HSS steel can cause a decrease in the hardness by as much as 4 HRC, which shortens the life of the edge. If you cool it in water, do not cool abruptly from a high temperature, since this can cause micro cracks invisible to the naked eye.

Grinding dust

The fine