+4

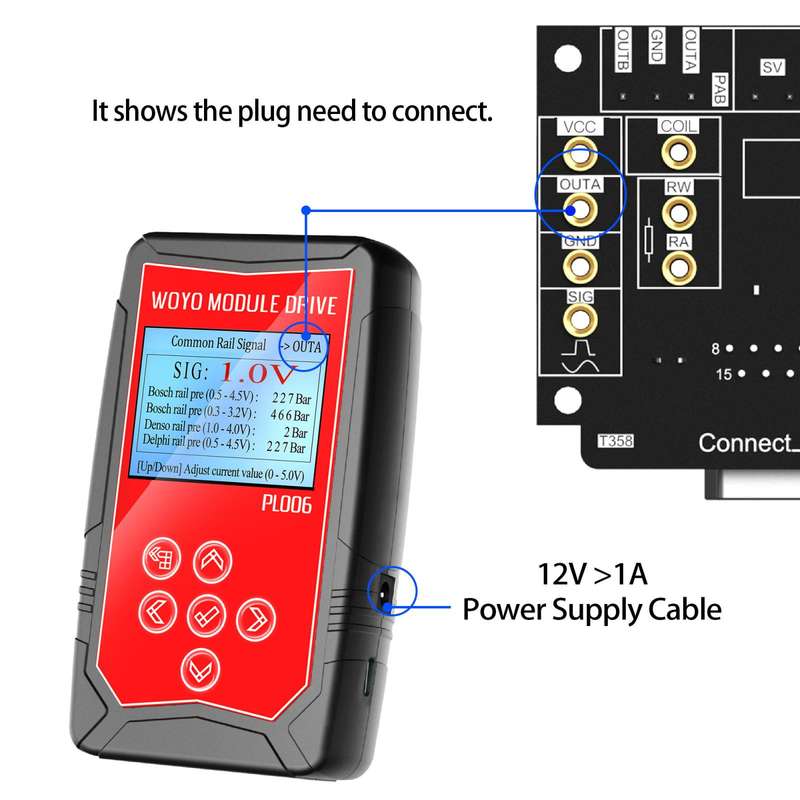

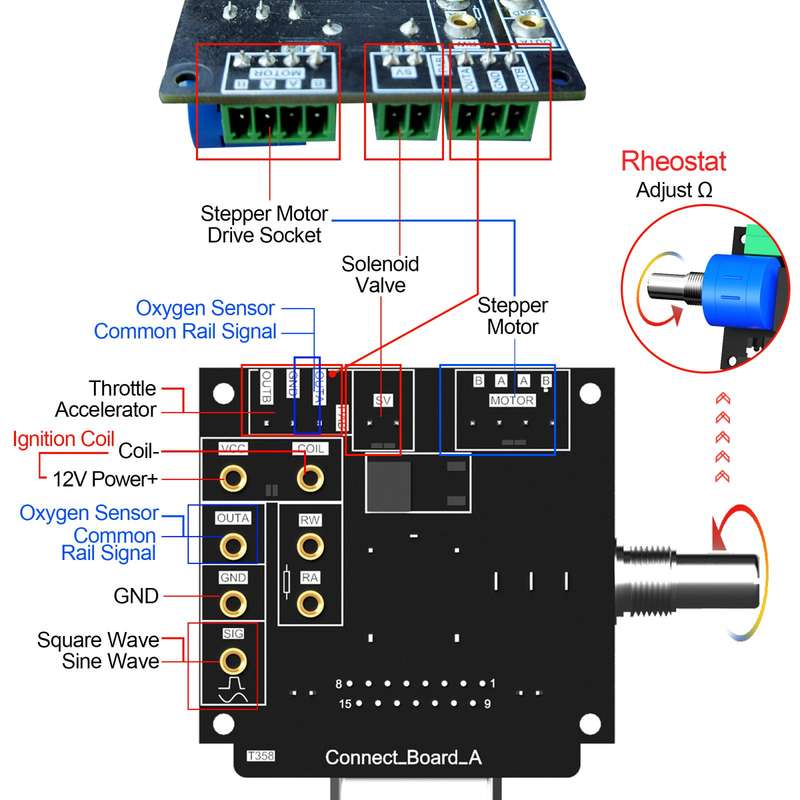

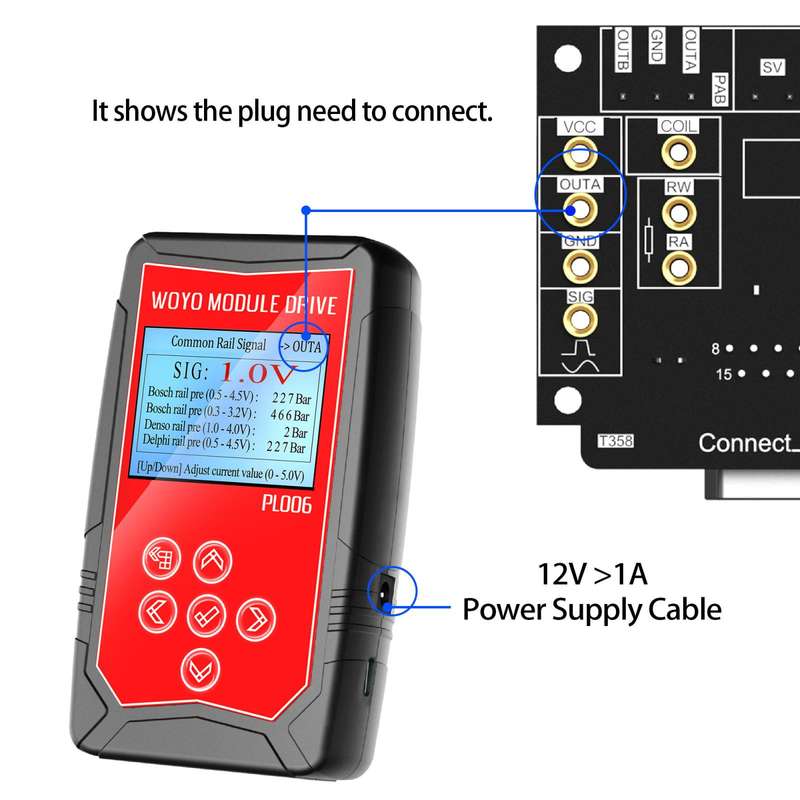

WOYO PL006 Automotive Component Sensor Offline Drive Tester for Automotive Maintenance and Inspectio

Indicative market price:

R2,547.00

33% off

Shipping

R35.00 Standard shipping using one of our trusted couriers applies to most areas in South Africa. Some areas may attract a R30.00 surcharge. This will be calculated at checkout if applicable.

Check my rate

Check my rate

The seller has indicated that they will usually have this item

ready to ship within 15 business days.

Shipping time depends on your delivery address.

The most accurate delivery time will be calculated at checkout,

but in general, the following shipping times apply:

Standard Delivery

| Main centres: | 1-3 business days |

| Regional areas: | 3-4 business days |

| Remote areas: | 3-5 business days |

Seller

Buyer protection

Get it now, pay later