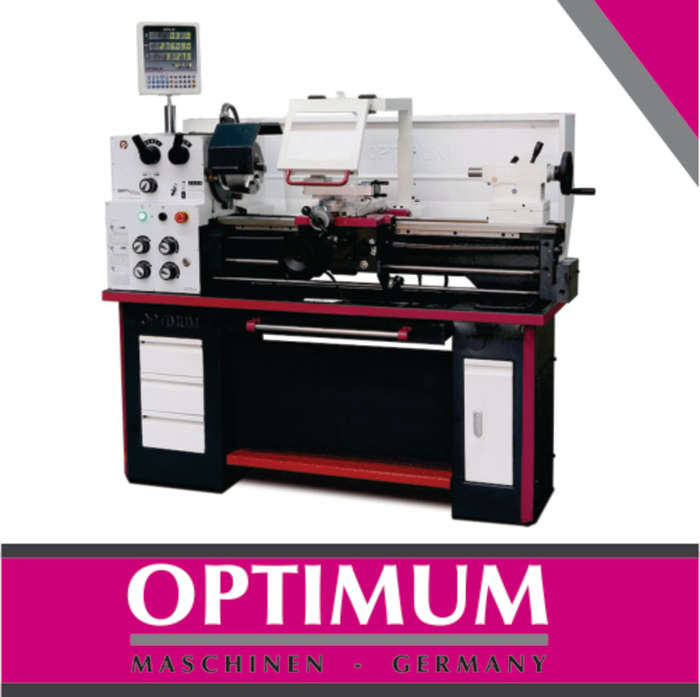

BL3402030 LATHE D330 X 830

Check my rate

| Main centres: | 1-3 business days |

| Regional areas: | 3-4 business days |

| Remote areas: | 3-5 business days |

| Main centres: | 1-3 business days |

| Regional areas: | 3-4 business days |

| Remote areas: | 3-5 business days |

Guide and traction spindle lathe

No Read Out

LATHE D330 X 830

Guide and traction spindle lathe

No Read Out

Technical Specifications

Length (product) 1,685 mm

Width / depth (product) 745 mm

Height (product) 1,320 mm

Weight (net) 430 kg

Power drive motor 1.5 kW

Electrical voltage 400V

Phase (s) 3 Ph

Current Type ~

power frequency 50 Hz

Spindle taper Camlock DIN ISO 702-2 No. 4

Spindle bore / rod diameter

Center height 165 mm

distance between centers 830 mm

Circumferential diameter over machine bed 330 mm

Circumference diameter in the bed bridge 170 mm

Circumferential diameter over cross slide 196 mm

Turning length in the bed bridge 196 mm

Speed range 70 2,000 min-1

Number of speed ranges 16

Travel X-axis 98 mm

Travel Y-axis 164 mm

Tailstock MK 3

Tailstock quill stroke 110 mm

Tailstock pinole diameter

spindle taper MK 5

Steel holder pick-up height max. 16 mm

Feed area along 0.052 1.392 mm / rev

Number of feeds along 32

Feed area flat 0.014 0.38 mm / rev

Number of feeds plan 32

Gradient Metric 0.4 7 mm

Number of slopes Metric 26

Gradient inches 56 4 g / in

Number of slopes inches 34

description

Fully equipped guide and traction spindle lathes. TH 3309D with digital position indicator DPA 21,

TH 3309V with brushless motor for stepless speed control and digital position indicator DPA 21.

Hardened and ground Z-axis guideway

Spindle mount Camlock DIN ISO 702-2 No. 4

Guaranteed concentricity of the spindle nose better than 0.015 mm

Motor protection switch (TH 3309 / TH 3309D)

DC 24 volt electrical system with two-channel safety circuit according to EN 23125

Lockable main switch

Right / left rotation on bed sled switchable

leading spindle

Machine base with tool compartment on the right side

Safety handwheels with release function in the X and Z axis

Emergency stop device with foot control

TH 3309D / TH 3309V

Digital position indicator DPA 21

User-friendly membrane keypad, splash-proof, closed and glare-free

Significant reduction in production times

Higher work accuracy

Error rate is reduced

X, Z0, Z axis with 8-digit display each

Clearly arranged keyboard

glass scales

TH 3309V: Powerful brushless drive

Especially quiet running

Approximately constant torque over the entire speed range

High power output

switch cabinet

24 volt DC power supply

All contactors and relays from Siemens or Schneider TH 3309V from Eaton

Room amenities:

main spindle

Running in oil bath

Gear wheels smooth, hardened and ground

sled

Precisely worked

Handwheels with adjustable fine scale 0.04 / 0.02 mm

Quadruple tool holder

All guides can be adjusted by wedge strips

Adjustment range upper slide ± 90 °

prism bed

Heavily ribbed

Induction hardened

precision ground

tailstock

For taper turning ± 10 mm adjustable

Tailstock quill and hand wheel with adjustable fine scale 0.025 mm

LED machine light

Integrated in chip protection

substructure

No toolboxes on the left, only panels

tool compartment

Right-left switch

two channels

tested according to EN 23125

hand wheels

decoupled

tested according to EN 23125

switch

with life cycle calculation

tested according to EN ISO 13849

chip pan

extractable

guide rails

Lathe chuck protection

tested according to EN 23125

Delivery Information

Fixed bezel passage Ø 19 70 mm

Running bezel passage Ø 16 50 mm

LED machine light

Reduction sleeve MK 5 / MK 3

Two fixed centering points MK 3

Quadruple steel holder 16 mm

Change gear set

substructure

Initial machine filling with quality oil

operating tool

Do not forget the lathe chuck!